Have you ever stopped mid-project to marvel at how quickly your SDS drill bit cut through concrete or masonry? If you’re wondering what makes these tools so powerful, you’re not alone. SDS drill bits have revolutionized heavy-duty drilling, combining efficiency, precision, and durability, even for the toughest jobs.

This post dives into how SDS drill bits work, the science powering their efficiency, and why they’ve become indispensable for masonry and construction tasks. Whether you’re a seasoned tradesperson or a DIY enthusiast tackling home projects, this guide will help you understand every detail of SDS technology.

What Are SDS Drill Bits?

Before we unravel how SDS drill bits work, let’s start with the basics. SDS stands for “Slotted Drive System” or “Special Direct System” (depending on the manufacturer). These drill bits were first developed by Bosch in the 1970s, and they’ve since become the go-to choice for drilling into tough surfaces like concrete, brick, and stone.

SDS bits are designed specifically for use with rotary hammer drills. They have unique shank designs that differentiate them from standard drill bits. These specialized bits lock into the chuck of an SDS drill to allow efficient transfer of force, making even the hardest drilling tasks manageable.

The Science Behind SDS Drill Bits

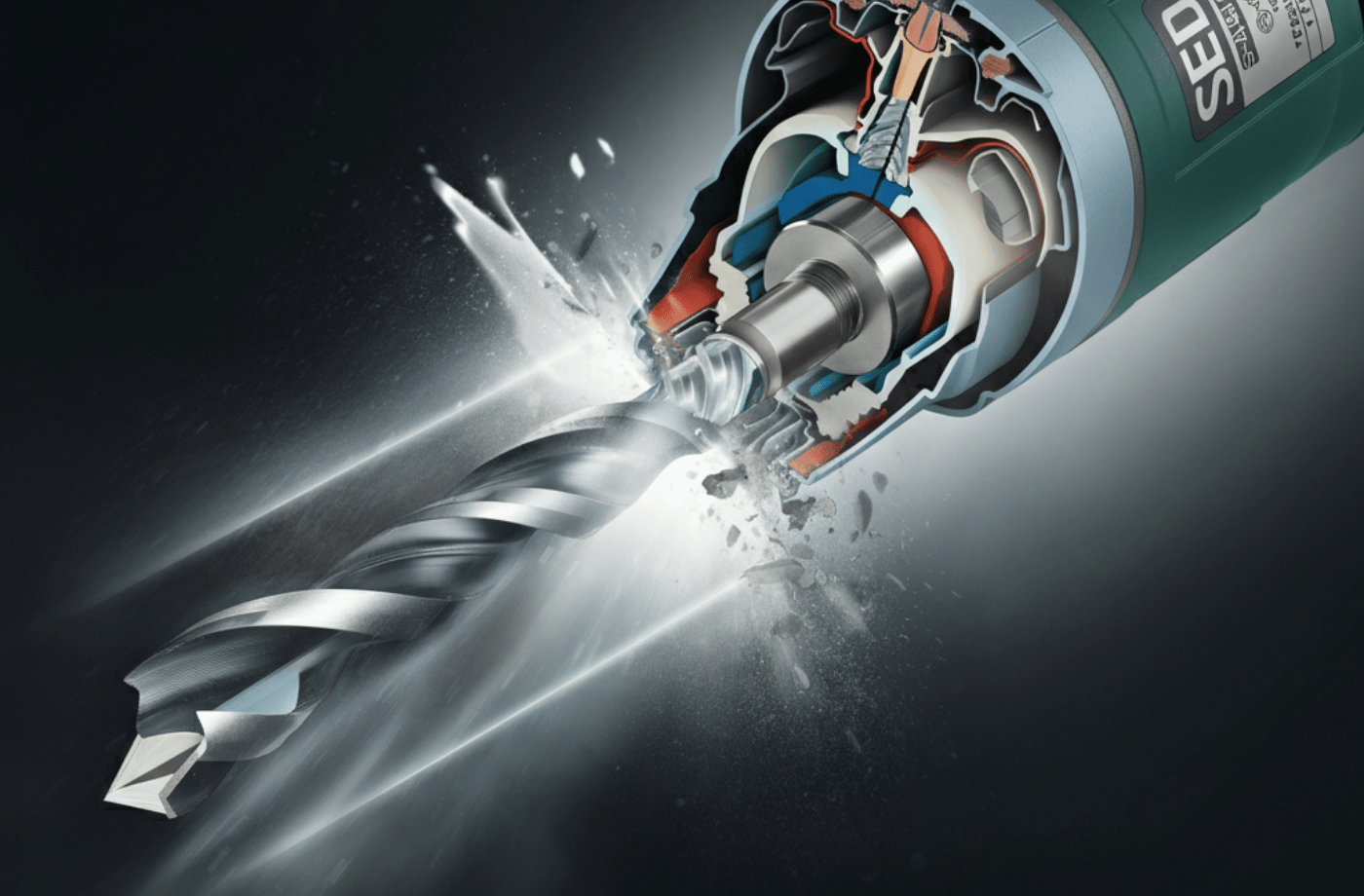

The magic of SDS drill bits lies in their design and interaction with the hammer drill. Let’s break down key elements of how they work.

1. The Grooved Shank Design

Unlike traditional round-shank bits, SDS drill bits have grooves on their shank (the part of the bit inserted into the drill). These grooves serve multiple purposes:

- Secure Fit: The grooves lock into the chuck mechanism, ensuring the bit doesn’t slip during heavy drilling.

- Efficient Energy Transfer: SDS drills transmit hammering force directly to the bit via these grooves, minimizing energy loss and increasing power.

2. Hammering and Rotary Action Combined

SDS drills combine two types of motion to optimize performance:

- Rotational Motion: Spins the drill bit, helping it carve through material.

- Hammering Motion: Delivers rapid, forward-percussive blows to break apart the surface.

The secret to SDS efficiency lies in allowing these two motions to occur simultaneously without power loss. The grooves on the SDS bit allow it to move slightly back and forth, amplifying the hammer action.

3. Material Composition

SDS drill bits are made to last. Most are constructed from durable materials such as tungsten carbide, known for its exceptional hardness and heat resistance. The tip of an SDS bit often has carbide inserts welded to it, which helps maintain sharpness even under tough conditions.

4. Dust Ejection Grooves

Another hallmark feature is the grooves or flutes running along the length of the bit. These are designed to remove debris as the bit drills deeper into the material. Efficient dust removal keeps the bit cool, reduces friction, and ensures smoother operation.

Why Use SDS Drill Bits? Key Benefits Explained

SDS drill bits have earned their stellar reputation for good reasons. Here are the primary benefits of using them.

Superior Performance on Hard Materials

Trying to drill into concrete or stone with a regular drill bit can be frustrating and time-consuming. SDS drill bits are specially engineered to handle these hard materials with ease, delivering clean and precise results.

Increased Drilling Speed

With the combination of rotational and hammering motion, SDS bits complete tasks significantly faster than regular drill bits. This increased speed makes them ideal for professional construction workers who can’t afford to waste time on-site.

Durability for Long-Term Use

The robust materials used in SDS drill bits mean fewer replacements, even under heavy use. Their longevity makes them a cost-effective investment for anyone who frequently works with masonry.

Convenient Bit Changes

Most SDS drills feature a quick-release chuck system. This allows users to swap bits effortlessly, saving time on multi-bit projects or when switching between drilling and chiseling tasks.

Reduced User Fatigue

SDS drills, paired with these bits, are designed to make heavy-duty tasks easier on users. With most of the energy transferred directly to the bit, less physical effort is required, reducing strain during long projects.

Types of SDS Drill Bits

There are various types of SDS drill bits tailored to specific tasks. Here’s a quick overview:

SDS-Plus

SDS-Plus is the most common type, perfect for light to medium-duty drilling. These bits are typically used for tasks like drilling anchor holes in concrete or brickwork.

SDS-Max

SDS-Max bits are for heavy-duty applications, such as drilling larger holes or demolition work. They have a larger shank, allowing them to handle higher impact and torque.

Specialty SDS Bits

Specialty bits include chisels, spade bits, and core bits. These are designed for specific tasks such as chiseling away tiles, creating wide openings in masonry, or drilling large-diameter holes.

How to Use SDS Drill Bits Effectively

To get the most out of your SDS drill bits, follow these best practices:

- Select the Right Bit: Choose between SDS-Plus or SDS-Max based on the material and task.

- Secure the Bit: Make sure the grooved shank locks into the chuck for optimal performance.

- Set the Drill Mode: Use the appropriate setting, whether it’s hammer drill mode (for concrete) or rotary mode (for softer materials).

- Monitor Speed and Pressure: Don’t push too hard. SDS drills are designed to deliver power with minimal force on your part.

- Regular Maintenance: Clean the dust ejection grooves and inspect the bit for wear after each use to ensure longevity.

Real-World Applications of SDS Drill Bits

SDS drill bits are trusted across various industries due to their versatility. Here’s how professionals use them:

- Construction: Creating anchor holes, breaking masonry, or demolition tasks.

- Electrical Work: Drilling channels in concrete walls for wiring installation.

- DIY Projects: Tiling jobs, fence post installations, or home renovations requiring sturdy drilling.

Invest in the Power of SDS Drill Bits

Understanding the science and benefits behind SDS drill bits shows why they’re a must-have for anyone dealing with masonry or heavy-duty drilling tasks. Their innovative design ensures that you always have the power and precision required to get the job done efficiently.

If you haven’t yet experienced the difference of SDS technology, now is the time. Whether you’re tackling a weekend DIY project or managing a large construction site, SDS drill bits will level up your drilling game.